JTEKT has developed a new product, the JTEKT Ultra Compact Bearing (JUCB), to narrow the bearings in the e-Axle, in anticipation of the expanding BEV (electric vehicle) market.

<Product Concept Diagram

About JTEKT Ultra Compact Bearing

The development and application of electric drive systems called e-Axle, which integrate gearboxes (including inverters, motors and differentials), is expanding dramatically in the course of the electrification of automobiles.

The demand for miniaturisation of the e-Axle, which corresponds to the core part of the drive source, is expanding in order to reduce electricity consumption, increase range and create better quality electric vehicles.

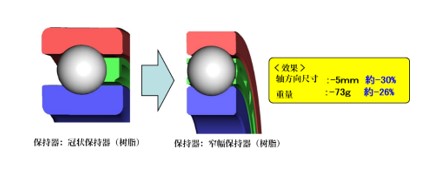

Jetagit had developed a highly rigid combination resin cage used mainly in HBEV (Hybrid Electric Vehicle) and BEV motors in 2016. The JUCB, developed this time, is based on a highly rigid combination resin retainer with a hole in the centre of the side of the retainer, enabling the narrowing of the bearing by reducing the width of the retainer to the limit. In addition, a free mould design and forming method was established to ensure the strength of the retainer even when the width is narrowed.

Features of the new product

● Keeping the bearing performance (strength and durability) unchanged, the unit length can be directly reduced

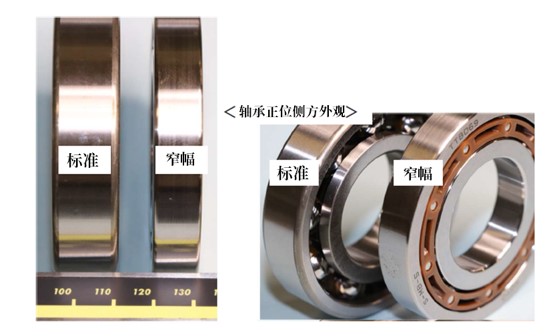

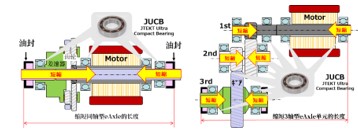

The bearing performance (strength and durability) is the same as that of the current product, and the bearing width has reached the limit of narrowing compared to our current product. By adopting the common size (6207), the axial dimension can be shortened by 5 mm (approx. 30%) and the weight can be reduced by 73 g (approx. 26%). As a result, the unit length can be reduced by mounting on the coaxial type or the 3-axis type e-Axle.

[Coaxial (left) and 3-axis (right) e-Axle cross-section and JUCB-based unit length reduction].

Contributing to the miniaturisation and lightweighting of the e-Axle by leveraging the synergies of the JETAG Group

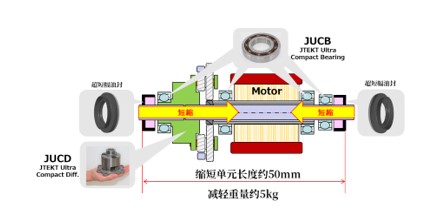

In the future, we will make use of the synergies of the Jetagit Group’s technologies, not only the JUCB, but also the announced JTEKT Ultra Compact Diff. and the ultra-short oil seal for the eAxle, which is currently under development, to propose technologies that will contribute to the electrification of vehicles.

The application of these three products in BEV electric drive systems, especially in the coaxial e-Axle with an output of 150Kw, for which demand is expected to increase, is expected to shorten the unit length of the e-Axle by approximately 50 mm and reduce its weight by approximately 5 kg. lightweighting.

In the future, JETAGAT will continue to contribute to the comfort of driving BEVs by making the e-Axle smaller and lighter, expanding the battery capacity to increase the range of BEVs, increasing the freedom of the e-Axle’s loading position, securing interior space and luggage space, increasing the freedom of the vehicle’s contours, and saving electricity consumption with the entire JETAGAT Group.

[Contributing to the miniaturization and lightweighting of the coaxial e-Axle by utilizing the electrification technologies that the JETAG Group possesses]

Future Prospects

JUCB will not stop at the BEV vehicle e-Axle, but will also respond to the need for miniaturization of various drive systems in Japan and abroad by applying them to industrial machinery such as construction machinery, agricultural machinery, robots, and drones.

In the future, JETAGAT will contribute to the realization of a low-carbon society by breaking down the barriers of each business unit and integrating the group as one, strengthening technologies that contribute to electrification, and practicing the manufacturing spirit of “for the earth, for society, and for the customer”.

The new products developed contribute to the SDGs, the United Nations Sustainable Development Goals

7.3 Double the global rate of energy efficiency improvement by 2030.

9.4 By 2030, all countries take action in line with their capacity to upgrade infrastructure, improve industry to make it more sustainable, increase resource efficiency and increase the adoption of clean and environmentally friendly technologies and industrial processes.